- Brands:

For the product price and more details, please contact us

This model is the third-generation laser welding machine of HaiLei Laser. It is widely used in mold repair services and mechanical parts repair. It can repair a variety of mold materials: S136, NAK80, 718, 738, P20, SKD-11, SKD -61, H13, W302, GS2344, GS2343, GS2080 and other mold steels in various countries. There will be no cracks and sand holes after welding. The hardness after welding can reach HRC60°hardness.

Principle of laser welding mold repair:

Hailei Die Laser Welding Machine is a special welding wire with high thermal energy generated in an instant that is welded to the damaged position of the mold, firmly welded to the original base material, and processed into a smooth surface by electric spark, grinding, etc. after welding, thereby repairing the mold.

product advantages:

1. Brand new design, high taste appearance

2. The laser head can move up and down, back and forth, left and right, up and down and left and right can be moved automatically, suitable for large molds, greatly improved operability.

3. The laser light path and power control system are independently designed, which is convenient to move and suitable for repairing various molds in various places.

4. Enhanced automatic precision workbench, optional up and down electric control, stepless speed regulation. The horizontal direction of the worktable adopts a ball screw. When welding large molds, the worktable can be moved freely and with high precision and stability.

5. Laser control precisely controls the laser power waveform, and the system presets optimized waveform values for different materials. As long as you choose the corresponding material, you can get the best results.

6. The heat-affected area is small, which will not cause deformation of precision instruments, large welding depth, firm welding, sufficient melting, leaving no traces of repair, and no convexity at the joint between the molten pool and the substrate.

Observation system:

Equipped with a special microscope observation system with a cross cursor, magnification 17.5X. The center of the cross cursor is aligned with the center of the laser spot (user adjustable). Equipped with a high-speed electronic filter protection device to protect the operator’s eyes from laser damage, relieve operator’s eye fatigue, and improve work efficiency.

Control System:

The improved built-in single-chip microcomputer is used for double closed loop precision control. Its stability and operation capability are far superior to the small microcomputer and control card used in similar products.

Gas protection system:

The dual-channel synchronous argon protection system is changed to make the argon protection better, the welding effect is firmer and more beautiful. At the same time, the original advantages are maintained-synchronous control with laser emission, which can save argon gas to the greatest extent.

Installation conditions and consumables:

220V 50HZ alternating current, providing more than 30A current (6 square meter line), stable voltage.

Environment: clean without dust or less dust, temperature: 55° F (13° C) to 82° F (28° C), humidity: 5% to 75% non-condensing.

Main consumables:

Xenon lamp, filter element, protective lens, water, welding wire, argon gas, electricity

Grouped equipment:

Water chiller, enhanced workbench, laser welding wire, welding wire clamp

Application field

Widely used in mold repair services and mechanical parts repair. It can repair and weld a variety of mold materials: S136, NAK80, 718, 738, P20, SKD-11, SKD-61, H13, W302, GS2344, GS2343, GS2080 and other countries' mold steels . There will be no cracks and sand holes after welding. The hardness after welding can reach HRC60°hardness.

Performance parameter

Model mold welding machine HL-M-200W-400W

Maximum laser power (W) 200W-400W

Laser wavelength (um) 1.064

Maximum energy of single pulse 90J

Laser welding frequency (HZ) 0.5-40

Laser welding depth (mm) 0.1-3.5

Pulse width (ms) 0.5-20

Spot size (mm) 0.2-2

Laser welding wire (mm) 0.2-0.8

Workbench Enhanced automatic workbench, optional electric workbench

Power of the whole machine <11KW

Power requirements Single-phase 220 15% VAC: 50Hz above 40A

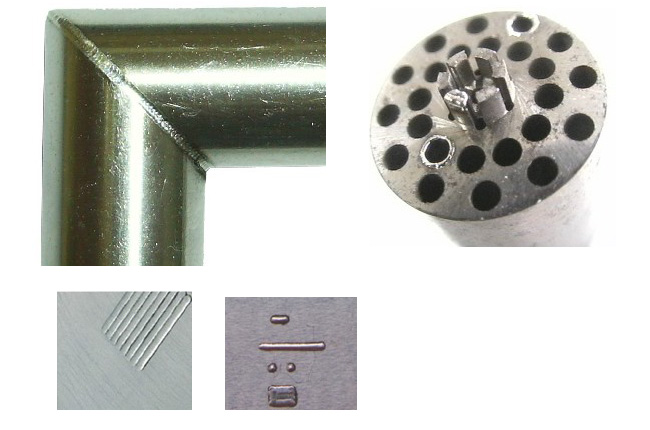

Sample display

Customer Reviews

100%Positive

0 CountCustomer Reviews