- Brands:

For the product price and more details, please contact us

The welding principle of stainless steel laser welding machine

The stainless steel laser welding machine uses a pulsed laser with a wavelength of 1064nm generated by a laser to radiate the surface of the workpiece after beam expansion, reflection, and focus. The surface heat is diffused to the inside through heat conduction, and the width, energy, peak power and peak power of the laser pulse are precisely controlled through digitalization. Parameters such as repetition frequency melt the workpiece to form a specific molten pool, thereby realizing laser welding of the workpiece, and completing precision welding that cannot be achieved by traditional technology.

Advantages of stainless steel laser welding machine

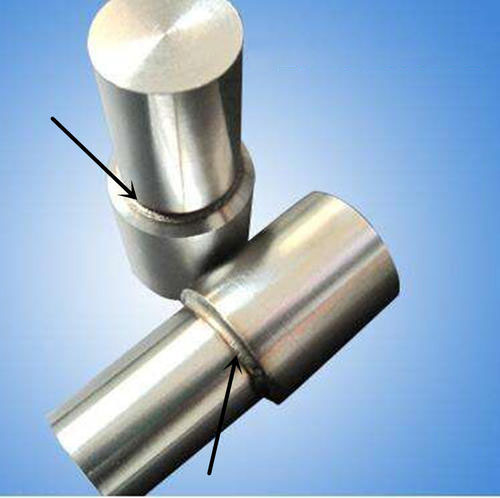

1. Fast speed, large depth and small deformation.

2. It can be welded at room temperature or under special conditions, and the laser welding equipment is simple. For example, when the laser passes through an electromagnetic field, the beam will not shift; the laser can be welded in vacuum, air and certain gas environments, and can be welded through glass or materials that are transparent to the beam.

3. It can weld refractory materials such as titanium, and can weld heterogeneous materials with good results.

4. After the laser is focused, the power density is high. When welding high-power devices, the aspect ratio can reach 5:1, and the highest can reach 10:1.

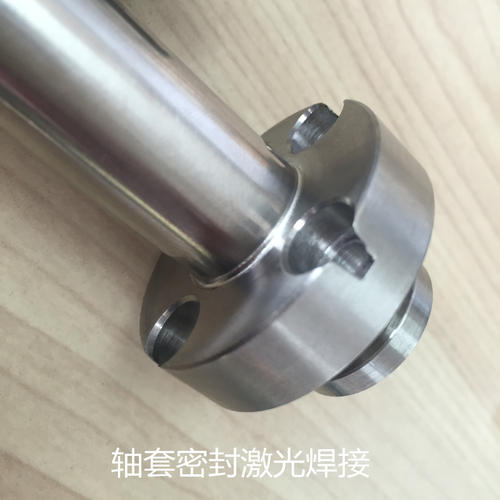

5. Micro welding is possible. After the laser beam is focused, a small spot can be obtained, and it can be accurately positioned, which can be used in the assembly welding of micro and small workpieces that are mass-produced automatically.

6. It can weld hard-to-access parts and perform non-contact long-distance welding, which has great flexibility. Especially in recent years, the use of optical fiber transmission technology in YAG laser processing technology has made laser welding more widely promoted and applied.

7. The laser beam is easy to realize the beam splitting according to time and space, and can carry out multi-beam simultaneous processing and multi-station processing, which provides conditions for more precise welding

Trial materials

Stainless steel, aluminum, copper, gold, silver, chromium, nickel, titanium and other metals or alloys can also be used for welding a variety of dissimilar materials. Such as copper-brass, titanium-gold, titanium-molybdenum, nickel-copper, etc.

Products Show

Customer Reviews

100%Positive

0 CountCustomer Reviews