- Brands:

TOP-3400 banner welding operation manual

Profession ● precise ● fluency

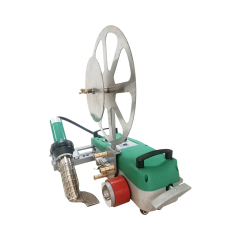

◆Small size, light weight and easy to carry

◆Digital display function

◆Wind is adjustable

◆Welding speed is fast

◆Do not have fold during the welding process

◆Having press-wheel, it is easy to move

◆Laser precision positioning system

Thank you very much for choosing our “Automatic Top-3400 banner welding”. We believe that this will be your best choice for your business. This equipment is designed professionally for ,sealing film or foil and homogeneous coating and PE-coated webbing belt lap welding that is make in PVC-P、PE、TPO ECB、CSPE、EPDM、PVDF. To help you understand the characters features of this equipment and know how to operate safely and keep in good condition etc. We give

you THE MANUAL OF INSTRODUCTIONS for your reference.

1.General instruction for safety:

Warning: The basic principal of safe protection should be followed to reduce the danger of fire in disaster, electric shock and personal harm. Please pay attention to the following items carefully before operation.

1.Keep the working place clean. Messing up and the disorderly working place cause disaster

2.Choose the work place carefully and use the machine in a bright and dry circumstance.

3.The electricity, controlling box and protective facilities have to be in the proper order after finishing daily work. The electrical power supply has to be switched off definitely.

4.The machine has to be stopped before gets maintenance or replacing the parts.

5.Use standard or indicated tools when dismantling or replacing parts.

6.For safety and the long life of the machine, please do not let the machine operates overtime.

7.If any special incidents happened, please stop the machine first for repairing, And do not deal with the special incident with improper procedures.

8. If the machine is operated on land, keep the work place clean and no dust there. If dust or something blocks the inhaling filter of heater, the heating wind can not come cut adequately and then temperature inside of filter will rise to let the heater burn down.

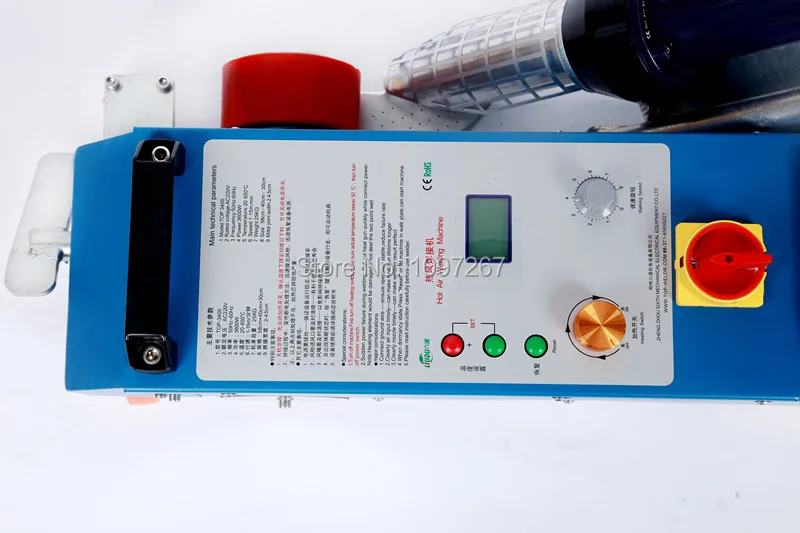

Specification:

Voltage:AC220V

Powe:3600W

Frequency:50/60HZ

Working Temperature:20-670degree(adjustable)

Welding speed:1-15m/min(adjustable)

Packing size:79*47*36cm

Welding Area:2-4cm

Net weight:30kg

certification:CE&ROHS

Operation:

1.First, make the picture smooth and tight, take joiner to accurate (about 2-4cm), fixed edges with tape or glue on the ground.

2.Set temperature and walk speed:connect power, set temperature and walk speed(according to thickness of banner), warm the welder.(in general temperature we set is 350-400 degree it means put set temperature button of the heat gun around 8.Walking speed is around 4,if the banner burnt.we can put temperature lower or make walking speed faster. If can not weld strong,put temperature higher or make walking speed slower).

3.Start welding:when actual temperature of the display screen reaches temperature that you want, we can begin to weld.put the walking handrail(at end of the machine)to left,machine Begin to work automatically.

Display actual temperature

At begin of weld,we should use one hand to take one banner up,then put nozzle between two banners,:

4.During welding,let hot air nozzle between two overlap pieces. And be make sure hot air nozzle and Rubber wheel walk in straight line.if not,please adjust by hand.

5.Finish welding:turn the walking handrail to the right ,machine stop walk,but before cut off the power,we should put the set temperature button to zero.when the actual temperature below 50 degree.we can cut off the main power.or it would damage heat system.

Tips:For first user,we can use waste banner to test and find proper temperature,we can do like this:take a small banner close the nozzle,if the banner hot melt quickly,it means,the temperature is OK,it not strong or burnt,we can increase or reduce temperature.we can also write down the temperature for this thickness of banner as sample.in next welding,based on this temperature.we just need to increase or reduce the temperature depends on thickness of banners.check the welding result:

Moving,Dismantlement,Installation,Cleaning:

1. Any part of this machine being bumped of fallen can cause some damage impossible to be repaired.So please pay attention to carry it.It is suggested to move the machine by manpower and put it down carefully.

2. Please check if there is damage or missed parts after unpack the machine.Any problem, please contact us or the local agent immediately.

3. The place for installation must be flat and the floor is strong enough to support the machine and moreover, the installation place should close to power supply.

4. Keep the installation place no dust and avoiding sunshine.

5. Please sweep away the anti-rust oil from the machine with detergent and re-lubricate with light lubricating oil after installation.

Notice:

1. During operating, if the surface cloth is dissolved and scorched or the cloth are not sticked together, please stop to adjust the temperature or speed.

2. During operating,if the seaming part is not in right position, please stop to adjust fixing position.

3. During operating, make sure clothes are flat so that stick together smoothly.

4. The hot wind of heater cannot touch the press-wheel or the rubber of press-wheel is easy to be burned down.

5.Adjust temperature to zero before turn off the heater.Switch off after 5-10 minutes.

Customer Reviews

100%Positive

0 CountCustomer Reviews