- Brands:

技术参数/Technical Specifications

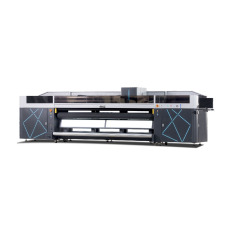

| 机器型号/Model | DS3200 / DS2000 | ||

打印技术/Print Technology | Piezo continuous drop-on demand(DOD) | ||

喷头类型/Head Model | RICOH GEN5 / RICOH GEN6 / KM1024I / KM1024A | ||

喷头控制/Print Head Control | 软件调整喷头温度,喷头电压Software Adjust Head temperature & Voltage | ||

| KCMYx2/KCMYx3/KCMYLcLmx2/KCMY//KCMYLcLm(白色选配/ white as optional)) | |||

打印幅宽/Maximum Printing Size | 3.30m / 2.05m | ||

打印分辨率/Print Resolution | 2880 dpi | ||

最快打印速度/Print Speed Up to | 150㎡/h | ||

墨水类型/INK Type | UV型墨水 / Environmental friendly UV/LED curable ink | ||

颜色配置/Color Profile | K C M Y Lc Lm (可选/optional) / K C M Y Lc Lm W V(可选/optional) | ||

刮墨装置/Auto.cleaning system | 有/Available | ||

供墨方式/Ink Supply System | 采⽤真空负压⾃动连续供墨 | ||

烘干装置/Drying System | LED UV灯固化 / LED UV lamp Curing | ||

包装尺寸/Package Size | 6340x1938x2168/5110x1790x2168(主机/Main frame) 3982x1750x1204/2400x1180x1739(辅助平台/SupportingTable) | ||

机器尺寸/Machine Size | 6020x2220x1775/4760x1570x1780(主机/Main frame) 6020x3732x1775/4760x3732x1780(辅助平台/SupportingTable) | ||

机器重量/Machine Weight | 3吨(主机)/1吨(扩展平台2个和收放布系统2个) 3Tons(Main frame)/ 1Ton (TWO extension platforms and Two Units of Media feeding & Take-up system) | ||

打印接口/Printing Interface | PCIE系统 / PCIE System | ||

电源要求/Power Requirement | 主机/Main frame 220V±10% 50HZ 3300W ⻛机/UV灯 220V±10% 50HZ 5000W | ||

环境要求/Environmental Requirements | 温度/Temperature 15 ℃ ~ 30 ℃ 相对湿度/Relative humidity 40% ~ 80% | ||

RIP软件/RIP Software | Printfactory/Caldera | ||

功能配置/Functional configuration | 智能恒压吸附(选配)、全自动导带纠偏(选配)、副墨罐独立温控、 折叠式扩展平台(选装),智能压差式负压供墨系统,人体工程力学 设计,THK静音导轨,直线电机(选配),LED冷光源固化,独立单 双卷收放布系统(选配),防撞继打功能,供墨液位缺墨,废液满报 警提示,缺料暂停打印,打印前报警,自动介质测高。 Intelligent constant pressure adsorption (optional), full-auto guidebelt guiding (optional), independent temperature control for auxiliary ink tank, folding extension platform (optional), intelligent pressure negative-pressure ink-supply system, human engineering mechanics design, THK mute guide, linear motor (optional), LED cold light source solidification, independent single and double winding take-up and feeding system (optional), anti-collision function, alarm tips when the ink supply level is short of ink and the waste liquid is full, print stop when it is short of ink, alarm before printing, and automatic media altimetry. |

以上数据如有更改,恕不另行通知,解释权归安徽力宇公司所有。

功能特点/Highlight Features:

1、LIYU Platinum Series UV guiding belt printer can stably print out a series of soft and hard materials such as soft film, coated banner, carriage sticker, high permeability film, reflective film, 3P cloth, KT board, paperboard, and polyvinyl alcohol. Besides, it has the remarkable characteristics of zero waste of printing materials and no error in long-size printing.

2、UV guiding belt printer can print accurately without calculating measurement compensation, and the printed materials are available immediately after printing; guiding cloth is not a must during printing, which can save materials and reduce costs; the printing media can be both hard and soft, which has a good versatility.

3、The printer is equipped with four-zone intelligent frequency conversion adsorption function, which can adapt to various soft and hard materials, and print more easily. In addition, soft materials are wrinkle-free, and hard materials are warp-free when printing.

4、The full-auto intelligent guiding belt guiding system allows printing long-format materials without deformation and deviation.

5、The original handle control with humanized design from the user's point of view can give an alarm before printing, select front and rear double-screen control, independent three-roll take-up and feeding system, etc. to provide better experience.

6、The automatic ink scraping system and cleaning equipment for print head can easily maintaining the print head without staining by the ink.

7、The optional independent front and rear take-up and feeding system can take-up and feed one roll of 3.2m material and two rolls of 1.6 m material at the same time. It can easily take-up and feed materials of various formats.

8、The optional front and rear keys and plate positioning control system can quickly position printing plates and print continuously.

Customer Reviews

100%Positive

0 CountCustomer Reviews