Textile Printing Machine Large Format Mimaki JV33 Digital Textile Printer

Quick Details:

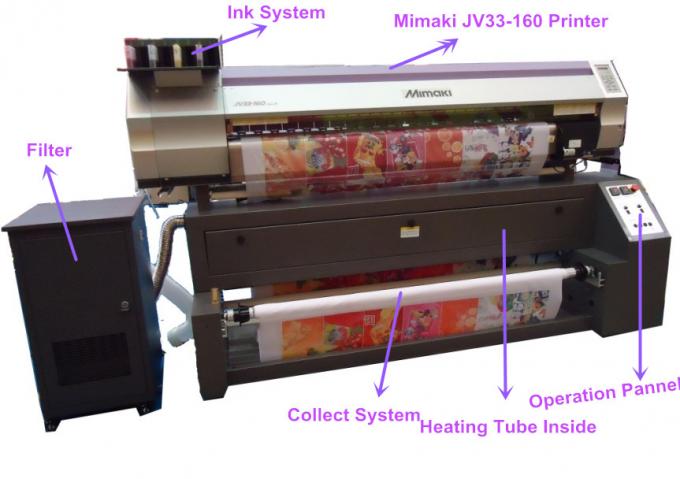

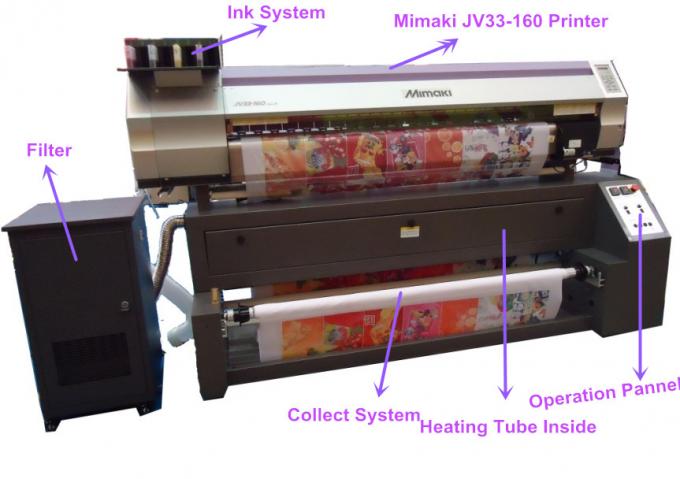

1. Mimaki JV33-160 Printer

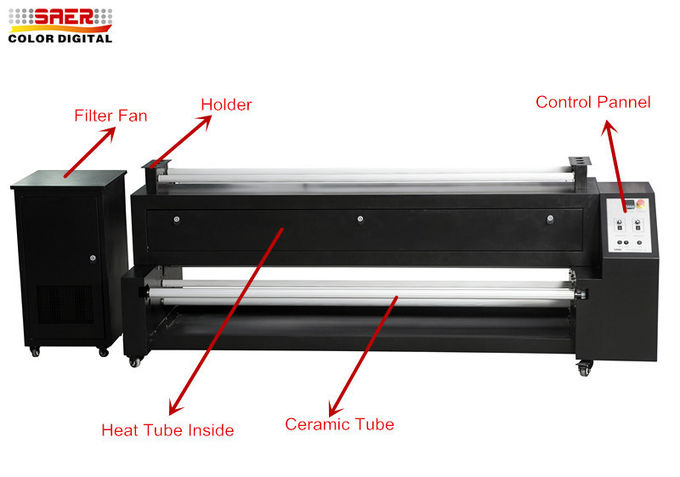

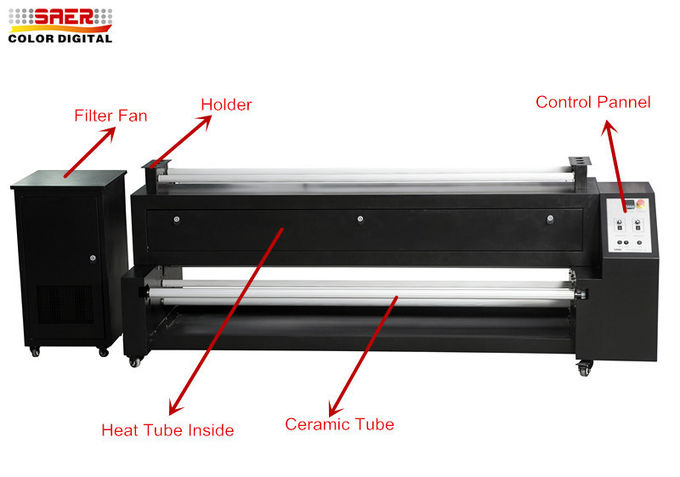

2. 1.6m Sublimation Heater(SR 1600)

3. Filter Fan

Specification:

- Low cost

- High productivity

- Directly print on textile Fabric,no need any medium.

Print Speed:

| Printing resolution and speed | Resolution(dpi) | Speed |

| 540x720(6pass) | 10.5m2/h |

| 720x720(4pass) | 15.5m2/h |

| 720x720(8pass) | 7.7m2/h |

| 1440x720(8pass) | 5.9m2/h |

| 1440x1440(16pass) | 3.0m2/h |

Detailed Specification:

| Product Name | Mimaki Textile Printer |

| Model | MSR1633 |

| Include | Mimaki JV33 With SR 1600 Heater |

| Print head | Piezo technology ,Epson DX5 printer head |

| Ink | Sublimation ink,reactive ink and pigment ink |

| Color mode | Dual KCMY(2C,2M,2Y,2K) |

| Nozzles | 180nozzles x 8lines |

| Print head higher | 1.5mm - 2.5mm(Adjustable) |

| Ink supply method | Block memed |

| Max materials width | 1625mm |

| Max printing width | 1600mm |

| Media Core Size available | 2 inch /3inch |

| Maximum weight for roll material | 40Kg |

| Interface | Ethernet 10Base-T |

| RAM | 128M |

| Printer power | AC100-120V/AC220-240V(Adaptive).50/60Hz±1Hz |

| Sublimation machine | AC220-240V.16A.50/60Hz±1Hz |

| Power consumption | Direct dye sublimation heater 3500W |

| Printer 5000W |

| Environment | Temperature:20-32°C,Humidity:40-60% |

| Packages | 3150X1000X1180mm 262x75x105mm |

Advantages:

SAER textile printer is under independent research and development. The price is 1/3 of that of traditional textile printers. It's of the world's leading piezoelectric sublimation technology.

1. Wider application field

After the modify of pannel board,this solution can convert the Mimaki printer to print images on Fabric directly.improved the application of heat transfer paper printing and wall paper printing.

2. Tension structures keep the printing material flat

Equipped with tension structure on front side and back side, as to keep the printing media flat. Even the artificial loaded media is not in the perfect straight status, this system can automatically correct the skewing in printing process.

3. Efficient heater

work together with the sublimation heater,with high temperature,Textile Printing Ink will be dried instantly before be collected by Automatic Take Up Roller.it can fade the color of printed image,the complated fabric can use to make flag ,banner and for home decoration directly.

4. Printing quality be ensured

The Media Collecting and Feeding System are synchronized so that printing quality be ensured.solve the stepping problem.

5. Bulk ink system

With this CISS, user can not only have similar image quality, but also avoid to use the expensive original inks.

6. Easy installation process

Even users with no experience can operate it within 2 hours.

SR 1600 Heater:

Heat Tube is far infrared blackbody ceramic tube,life is longer,can reach 10000 hours

Have a oil connection slot,so the waste oil won't drop on the fabric.

Speed can reach 20-100m / hour,so one machine can work with 4 printers at the same time.

Application:

On polyester fabric:outside to make beach flag,banner flag etc.

indoor to make curtain,table cloth,wallpaper etc.

On Cotton fabric: to make clothes,bedsheets directly.

On Linen fabric:to make skirts etc.

After Sales Service:

1. Provide 12 months warranty for print boards and motors for our printers and online support

2. When you have some technical problems,please send detail description,photos or video,then our technician will give the resolution accordingly during 24 hours.

3. There are completed English user manuals to guide you easily install ,operate and maintain the printer. It’s clear and easy to understand.

4. Free training is availabe when you need it, you are welcome to our factory to obtain the skills. or we also send engineer to your company to make a training for your people.

with 15 years export experience in the large format printers industry, High quality, safe packing, on-time delivery and good after service are OUR KEY.

Detail Pictures:

Printed Samples:

payment and delivery

Customer Reviews

100%Positive

0 CountCustomer Reviews