- Brands:

| Thickness: | Customized | Width: | Customized |

|---|---|---|---|

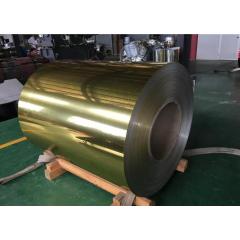

| Color: | Silver Mirror | Surface: | Polished |

| Material: | Aluminum Alloy | Application: | Interior Panel |

| High Light: | aluminum roll stock,polished aluminium sheet | ||

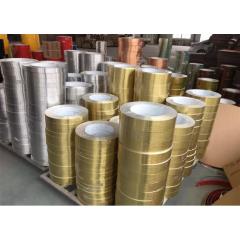

Heat Resistant High Reflective Aluminium Coil , High Weather Resistance Installation Convenient

Description

Place of Origin: Hunan, China (Mainland)

Model Number: 1050 1060 1100

Application: Construction

Thickness: 0.10mm-20mm

Width: 600mm-1250mm

Alloy Or Not: Is Alloy

Grade: 7000 Series

Surface Treatment: Coated

Temper: O - H112

Color: Required

Surface: Powder Coated

Shape: Sheet, Coil, Channel Letter

Type: Coil,plate,Roll

Material: 1050/1060/1070/1100

Application Of Mirror Polished Aluminum Coil

Lighting: Such as grille lamp, lampshade, grille, diffuser of fluorescent lamp

Reflector plate of solar energy

Exterior of construction

Interior decoration, such as aluminum buckle plate, ceiling, curtain wall;

Elevator

Nameplate

The face panel of household appliance, microwave oven, refrigerator, etc.

More Uses

●. Typical application: Matal sheet for marine and transportation vehicles, inner and outer siding, board of railway carriage, storage device of oil and chemical industry, equipment panel and medical machinery etc..

●. Building exterior curtain walls, Advertisement board display platforms and signboards, Wallboards and ceilings for tunnels

●. Decoration and renovation additions for old building, decoration of interior walls, ceilings, bathrooms, kitchens,and balconies

Alloy Chemical Composition

| CHEMICAL COMPOSITION | ||||||||||

| ALLOY | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | AI |

| 1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | / | / | 0.05 | / | 99.50 |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | / | / | 0.05 | / | 99.60 |

| 1070 | 0.25 | 0.25 | 0.04 | 0.03 | 0.03 | / | / | 0.04 | / | 99.70 |

| 1100 | Si+Fe:0.95 | 0.05-.020 | 0.05 | / | / | 0.10 | / | / | 99.00 | |

| 2024 | 0.50 | 0.50 | 3.80-4.90 | 0.30-0.90 | 1.20-1.80 | 0.10 | / | 0.25 | 0.15 | Remainder |

| 3003 | 0.60 | 0.70 | 0.05-0.20 | 1.00-1.50 | / | / | / | 0.10 | / | Remainder |

| 3105 | 0.60 | 0.70 | 0.30 | 0.30-0.80 | 0.20-0.80 | 0.20 | / | 0.40 | 0.10 | Remainder |

| 5005 | 0.30 | 0.70 | 0.20 | 0.20 | 0.50-1.10 | 0.10 | / | 0.25 | / | Remainder |

| 5052 | 0.25 | 0.40 | 0.10 | 0.10 | 2.20-2.80 | 0.15-0.35 | / | 0.10 | / | Remainder |

| 5083 | 0.40 | 0.40 | 0.10 | 0.40-1.00 | 4.00-4.90 | 0.05-0.25 | / | 0.25 | / | Remainder |

| 5754 | 0.40 | 0.40 | 0.10 | 0.50 | 2.60-3.60 | 0.30 | / | 0.20 | / | Remainder |

| 6061 | 0.40-0.80 | 0.70 | 0.15-0.40 | 0.15 | 0.80-1.20 | 0.04-0.35 | / | 0.25 | / | Remainder |

| 6063 | 0.20-0.60 | 0.35 | 0.10 | 0.10 | 0.45-0.90 | 0.10 | / | 0.10 | / | Remainder |

| 6082 | 0.70-1.30 | 0.50 | 0.10 | 0.40-1.00 | 0.60-1.20 | 0.25 | / | 0.20 | / | Remainder |

| 7050 | 0.12 | 0.15 | 2.00-2.60 | 0.10 | 1.90-2.60 | 0.04 | / | 5.70-6.70 | 0.06 | Remainder |

| 7075 | 0.40 | 0.50 | 1.20-2.00 | 0.30 | 2.10-2.90 | 0.18-0.28 | / | 5.10-6.10 | 0.20 | Remainder |

Features

●. Excellent stripping degree & torsion strength

●. Easy processing & installation

●. Outstanding fireproof features

●. Excellent impact resistance

●. Perfect

Customer Reviews

100%Positive

0 CountCustomer Reviews