- 商家货号:D6

- Brands:

For the product price and more details, please contact us

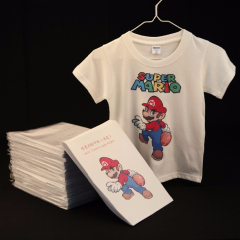

Product: Anti-sublimation printable pu heat transfer vinyl;

Printer: Mimaki, Roland, etc,

Ink: Eco-solvent ink;

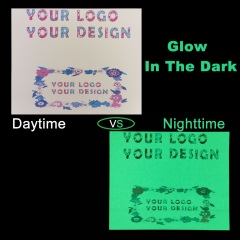

Advantages: Anti-sublimation;

1. Introduction

Our newly developed anti-sublimation eco-solvent heat transfer paper/film(AS-1) is a kind of heat transfer material that can

effectively eliminate the phenomenon of strike through when applied to sublimation garments, and it is especially applied to ecosolvent

inkjet printers( eg. Roland). Any more, made of environmental friendly material, it is non-toxic and harmless to human

body. Patterns transferred are characterized as low transfer temperature, high structure strength, high-resilient, soft, resistant to

yellowing, cutting smoothly and bearing superior color fastness to washing. It is suitable for transferring exquisite images onto

various textile materials and leather, like gym suits, T-shirts, hats, bags, sofa cushions, mouse pads, etc.

This series has made the garment printing process simple. Instead of plate making, you can print the exquisite image directly

on this material, then by cutting and removing the blank part, and also following the instruction to transfer image onto fabrics. It

is particularly suitable for the production of small quantities of personalized products.

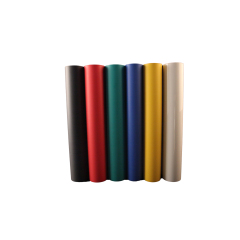

2. Specification

500mm×30m 、610mm×30m (Other specifications, pls consult the salesman)

3. Applicable Printer

Eco-solvent inkjet printers, eco-solvent inkjet printer/cutters, like Roland Vs-640/540/420/300,BN-20, etc.

4. Operation Instructions

◆Printing

-Printer setup. Set the print parameters before printing. Print wishful image onto the dark-colored eco-solvent transfer

paper.

◆Cutting

- Cut out the image manually or by machine. (suggest to use30° lettering knife.)

◆Image Removing

-Remove the image printed top layer of transfer paper from the paper back to transfer film.

◆Transferring

-Preheat the heat press machine to 150-165

-Place the coating onto the textile with the printed image facing upwards.

Transfer for 30-60 seconds and then remove the textile, cool peel the transfer film. (transfer film can be used multiple

times.)

◆Washing

-It’s best not to wash the textile in 24 hours after transferring.

-Washing the textile in cold or warm water under 40℃. Do not use strongly alkaline

detergents or bleach. Avoid rubbing the transfer pattern when hand washing. Do not wring.

Line dry in shade recommended.

-Do not dry-clean.

Customer Reviews

100%Positive

0 CountCustomer Reviews