- Brands:

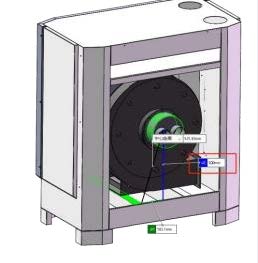

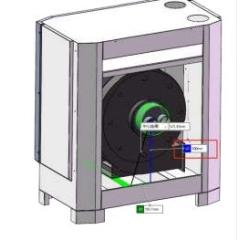

1. Equipment Picture

2. Equipment Application

Supporting laser cutting machine, CNC stamping, various CNC processing or other machining deburring front production line. Equipment through straight line processing, sanding belt and multiple groups of sanding line wheel rotation, revolution, alternate, can be a real uniform removal of parts surface, contour edge and hole edge burr and uniform chamfering.

3. Equipment Schematic Diagram

4. Equipment Performance and Characteristics

1) Internal and external contour deburring, fillet finishing, because it is flexible processing all after polishing, brush grinding and film processing of sheet metal parts, do not hurt the surface size and film covering.

2) It is suitable for the burr removal of sheet metal parts on the same plane or the same plane processed by CNC punching and shearing machine. Burr removal after laser cutting; flame cutting or plasma cutting slag removal.

3) Instead of burr, use file, scraper or electric or pneumatic tools for grinding process processing scheme, so that the workpiece is polished more evenly, more safety, and effectively reduce labor costs and improve production efficiency.

4 ) Visual and free adjustment of grinding and stroke parameters can only polish the contour and sharp edge of the workpiece without damaging the surface, and effectively protect the coating of the workpiece. It suitable for galvanized sheet, coated aluminum sheet, copper sheet, stainless steel sheet and other surface protection requirements of the workpiece.

5) Adopting turbine vacuum adsorption technology, workpiece can be firmly adsorbed during grinding, bending workpiece and special-shaped workpiece can also be adsorbed and polished, greatly improving the processing range and efficiency, and eliminating pressure loss or failure of vacuum adsorption system due to blockage. More special magnetic suction system, when the workpiece has conditions to use magnetic adsorption fixed, greatly reduce the power consumption of equipment, energy conservation and environmental protection, the maximum cost of production.

6) The equipment adopts Delta Plc control system, simple and convenient operation, convenient and quick adjustment of grinding quantity.

7) For the product type, choose magnetic adsorption, equipment power consumption will be greatly reduced.

8) The machine uses general consumables in the market, and can also be customized to import sand wheel to improve production efficiency and meet the special requirements of products.

9) The equipment has the interface of installing dust collector to absorb the dust, metal chips and dust generated by the equipment in the process of working. Separate dust removal equipment or existing equipment in the factory can be selected.

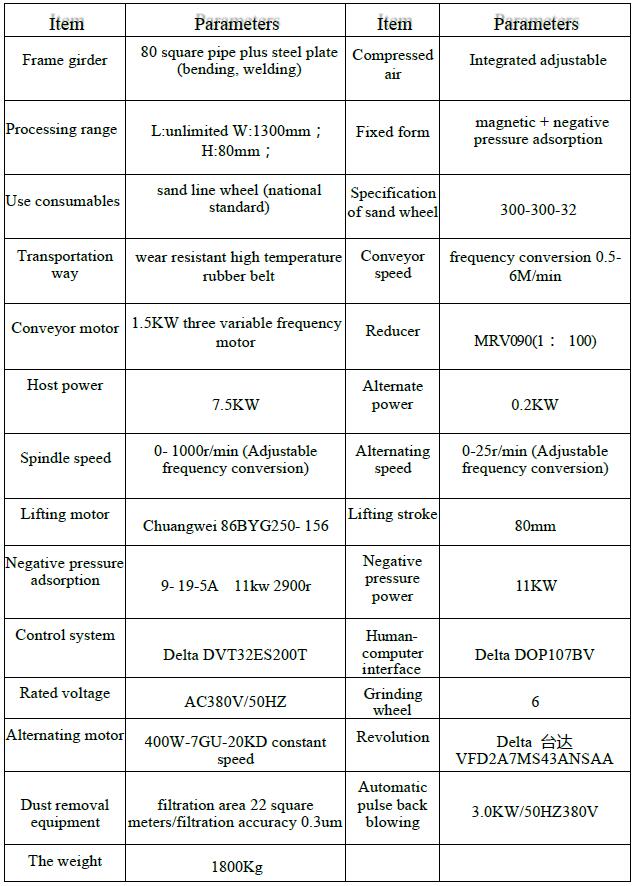

5. Equipment Configuration and Related Technical Parameters

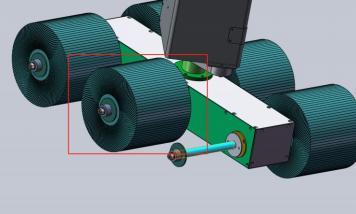

6. Structural Composition

9. Host frame: (T8 column, T8 beam, integrated table, support base for each component, etc.) one set

1 0. Conveying mechanism: (servo conveying power, conveyor belt, front and rear rollers, balance adjustment, etc.) one set

11. Host head: (transmission mechanism, main shaft, accessories, bearings, imported seals,etc.) one set

12. Lifting mechanism: (stepping drive motor, precision column screw, height detection, limit control, etc.) one set

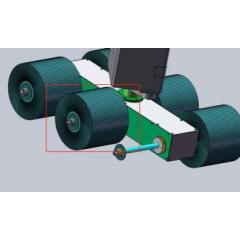

13. Revolution (alternating) system: (brushless motor, drive shaft, bearing, etc.) one set

14. Control system: (control box, human-computer interface, height control display, vector frequency conversion, etc.) one set

15. Magnetic adsorption system: (Magnetic plate holder, magnetic wire, Magnetic plate protection, etc.) one set

16. Negative pressure adsorption system: (fan, negative pressure box) one set

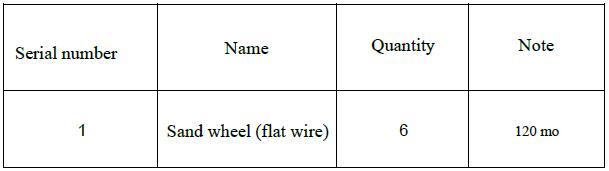

7. List of Spare Parts and Main Wearing Parts

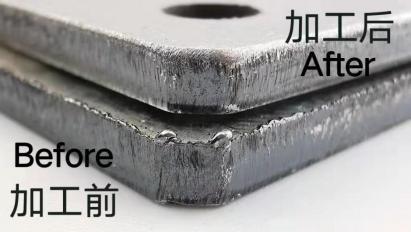

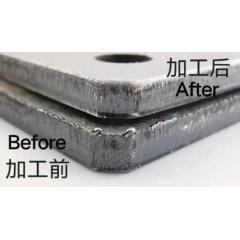

8. Contrast Effect Before and After Grinding

Customer Reviews

100%Positive

0 CountCustomer Reviews