- Brands:

1.Equipment interior picture

2. Equipment use

This equipment is a dry sand belt model with double sand frame. It is mainly used to deal with deburring, workpiece edge and hole deburring effect. The workpiece surface is sanded to make the contour edges around the workpiece surface and in the hole smooth and rounded, and the metal sheet surface wire drawing, peeling, polishing and other processing. Aiming at the burr produced in the process of stamping, shearing, laser machine cutting, plasma cutting and so on, it can remove the burr in all directions at one time, and the processing process is safe and reliable, so that the workpiece can achieve the perfect effect.

3. Working principle of the equipment

This equipment is through the dry processing equipment, first through a group of coarse sand belt mechanism to remove the surface of the workpiece slag particles, large flange and other large burrs.

4. Equipment performance and characteristics

1 ) Surface deburring, finishing, sand belt can be replaced at will, the product finish will change accordingly.

2 ) It is suitable for the burr removal in the holes of sheet metal parts processed by CNC punching and shearing machine or relative to the same plane.

3) Replace burr with file, scraper or use of electric, pneumatic tools for grinding process treatment scheme, so that the workpiece grinding more uniform, safer and effectively reduce labor costs to improve production efficiency.

4) The equipment adopts Chint button system, so the operation is simple and convenient. The thickness digital display can be upgraded electrically, fine- tuned, and the grinding amount can be adjusted conveniently and quickly.

5) This machine uses general consumables in the market, and can also be customized imported sandpaper to improve production efficiency and meet the special requirements of products.

6) The equipment is equipped with the interface of dust collector, which can suck the dust and metal chips and dust generated by the equipment in the process of working. It can choose separate dust removal equipment or link the existing equipment of the factory.

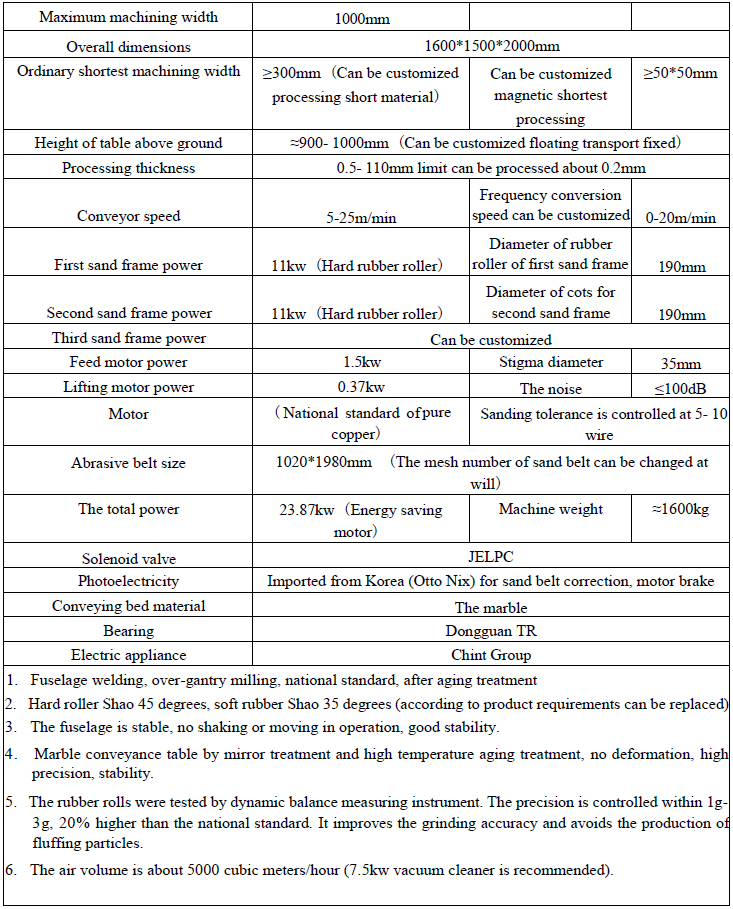

5. Equipment configuration and related technical parameters

6. Structural components

1) Main frame: One sand frame, each component support seat body, etc.

One set

2) Conveying mechanism: non-pole conveying power, conveyor belt, front

roller, balance adjustment, etc.

One set

3) Lifting mechanism: precision column screw, magnetic ring inductor,

limit switch, etc.

One set

4) Control system: electronic control, button panel high precision, height

numerical control display, etc.

One set

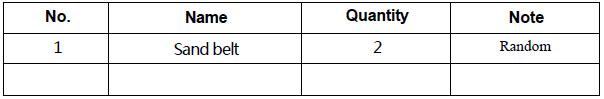

7. List of spare parts and main wearing parts

8. Equipment advantages

1) The equipment adopts button control system, easy to operate, digital monitoring grinding friction resistance, convenient and quick adjustment of grinding amount.

2) This machine uses general consumables in the market, without special customization or designated suppliers to buy, eliminate the limitations of imported equipment or some domestic brand equipment binding consumables, greatly reduce the user's cost. (Specification: 40- 1000 molybdenum)

3) Custom sand belts are also available to improve production efficiency and meet special product requirements.

4) The equipment is equipped with the interface of pulse dust collector, which can suck away the dust, metal dust and dust generated by the equipment in the process ofworking, and collect them in the dust collection box of the equipment to keep the working environment clean. The dust collector itself has the recoil function, which can automatically clean the filter element to prevent the dust removal failure due to blockage.(Optional)

5) The whole equipment (except wearing parts) is guaranteed for one year and maintained for life.

Customer Reviews

100%Positive

0 CountCustomer Reviews